Unlocking Excellence in Manufacturing: The Role of Metal Fabricators and Plastic Injection Molding Manufacturing Companies in Modern Industry

In today’s fast-evolving manufacturing landscape, businesses are constantly seeking innovative, cost-effective, and high-quality solutions to meet the demanding needs of diverse industries such as automotive, electronics, consumer goods, and healthcare. Two pivotal pillars underpin this dynamic environment: metal fabrication and plastic injection molding manufacturing companies. Among the industry leaders, companies like DeepMould exemplify excellence, innovation, and reliability, ensuring clients receive products of unparalleled precision and durability.

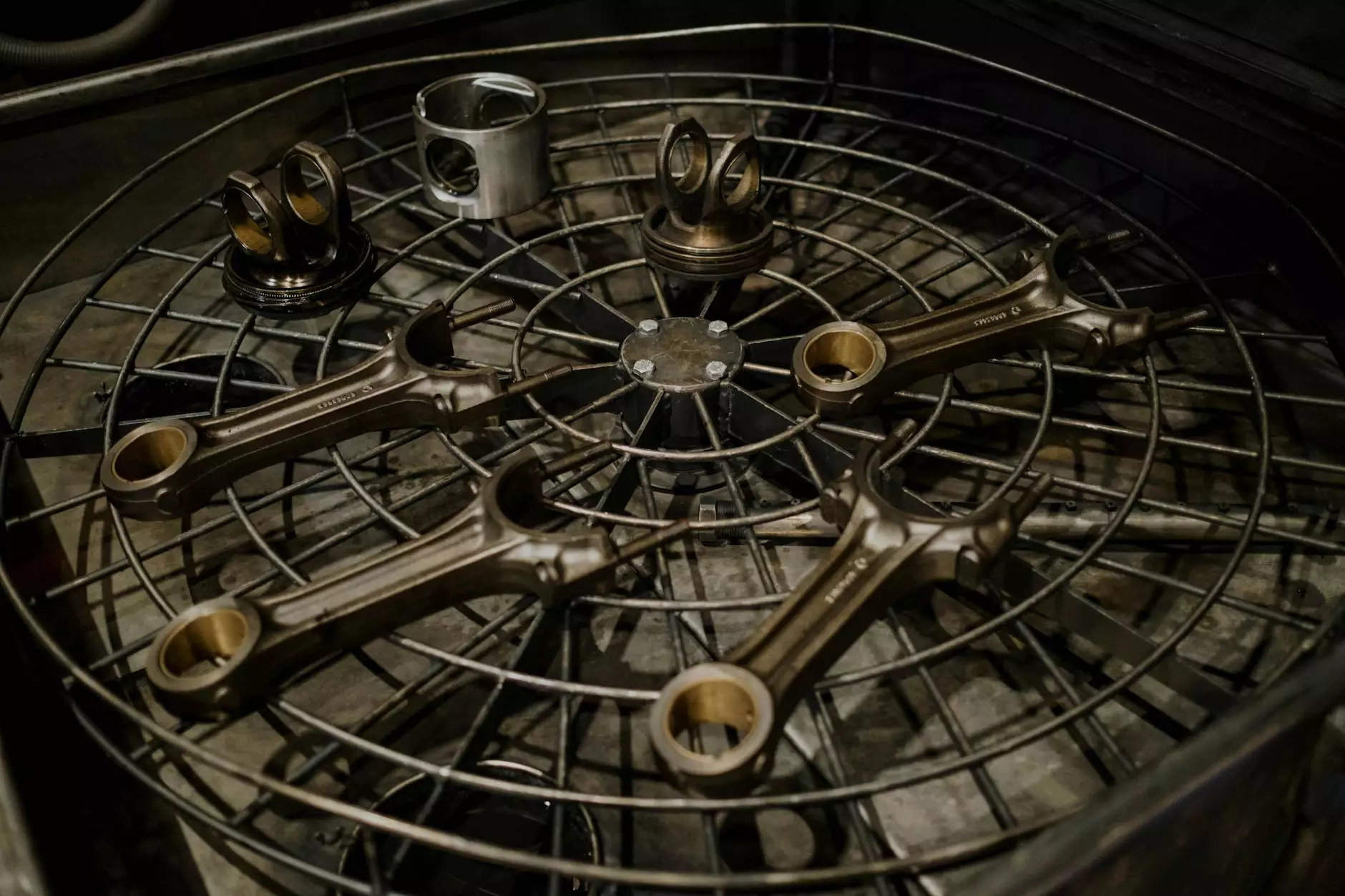

Understanding Metal Fabricators: The Backbone of Structural and Functional Components

Metal fabricators are specialized in transforming raw metals into intricate components through a variety of manufacturing processes. Their expertise extends across several industries, contributing to infrastructure, transportation, aerospace, and beyond. Key processes employed by metal fabricators include:

- Cutting — utilizing laser, plasma, or waterjet techniques for precise sectioning

- Bending and forming — shaping metals into desired angles and curves

- Welding and joining — creating durable connections between metal parts

- Machining — performing drilling, milling, and turning to achieve accurate dimensions

- Surface treatment — applying finishes like coating, galvanizing, or painting for corrosion protection and aesthetics

Advanced metal fabricators leverage state-of-the-art technology such as CNC machinery, robotic systems, and 3D modeling to deliver high-precision components that meet strict industry standards. Durability, strength, and precision are the hallmarks of expertly fabricated metal parts, essential for structural integrity and high-performance applications.

High-Quality Plastic Injection Molding Manufacturing Companies: Innovating with Precision

The plastic injection molding manufacturing companies sector is a cornerstone of modern manufacturing, providing cost-efficient, scalable, and complex plastic components for countless applications. These companies utilize advanced molds and injection machines to produce parts with intricate geometries, tight tolerances, and consistent quality. Key benefits of working with top-tier plastic injection molding companies include:

- Rapid prototyping — enabling quick design iterations and testing

- High-volume production — ensuring uniform quality over millions of units

- Material versatility — ranging from thermoplastics and thermosets to advanced composites

- Cost efficiency — reducing per-unit costs with scale

- Design flexibility — allowing complex and elaborate parts that are difficult to manufacture with traditional methods

Leading companies like DeepMould employ automated systems, sophisticated mold designs, and rigorous quality control processes to deliver parts that meet the highest standards. Their expertise ensures that project requirements—from consumer electronics to medical devices—are met with reliability and precision.

The Intersection of Metal Fabrication and Plastic Injection Molding

While metal fabrication and plastic injection molding manufacturing companies serve different primary functions, their collaboration results in comprehensive manufacturing solutions. The synergy between these processes enables:

- Integrated product development — combining metal and plastic parts for optimized performance

- Cost-effective manufacturing — reducing assembly complexity by designing integrated components

- Innovative applications — designing lightweight, durable, and functional products for high-tech industries

- Streamlined supply chains — working with integrated manufacturers like DeepMould to coordinate production cycles and delivery

By leveraging both metal fabrication and plastic injection molding, visionary companies can develop sophisticated, durable, and cost-efficient products tailored to the specific needs of each market segment.

Why Choose DeepMould as Your Manufacturing Partner?

Established as a leader in the metal fabricators industry, DeepMould combines decades of expertise with cutting-edge technology to deliver superior manufacturing services. Their specialization in plastic injection molding manufacturing complements their metal fabrication capabilities, creating a comprehensive ecosystem for product development.

Some of the compelling reasons to partner with DeepMould include:

- End-to-end manufacturing solutions — from prototyping to mass production

- State-of-the-art equipment — including CNC machines, robotic assembly, and high-precision injection molding machines

- Rigorous quality assurance — adhering to ISO standards and conducting meticulous inspections

- Customized services — tailored solutions for unique client specifications

- Environmental responsibility — sustainable manufacturing practices and eco-friendly materials

In addition, DeepMould boasts a proven track record of delivering complex projects with tight deadlines, all while maintaining an unwavering commitment to quality and customer satisfaction. Their ability to integrate metal and plastic manufacturing under one roof makes them an ideal partner for innovative product development.

Key Trends Shaping the Future of Manufacturing

The manufacturing industry continues to evolve rapidly, driven by technological advancements and changing market demands. Some prominent trends include:

- Automation and Industry 4.0 — integrating IoT, artificial intelligence, and robotics for smarter, more efficient production lines

- Additive manufacturing — 3D printing as a complement to traditional manufacturing processes for rapid prototyping and bespoke parts

- Sustainable manufacturing — reducing waste, utilizing recyclable materials, and implementing energy-efficient practices

- Customization and personalization — leveraging flexible manufacturing systems to meet individual customer needs

- Global supply chain optimization — adopting digital tools to streamline logistics and inventory management

Leading companies like DeepMould are proactively adopting these trends, ensuring they remain at the forefront of innovation and continue to deliver excellence to clients worldwide.

Choosing the Right Partner for Your Manufacturing Needs

When selecting a metal fabricator or a plastic injection molding manufacturing company, consider the following factors:

- Experience and expertise in your specific industry and application

- Technological capabilities — ensuring they have advanced machinery and quality control systems

- Certifications and standards compliance — ISO, ASTM, or industry-specific certifications

- Portfolio and client references — reviewing past projects and client testimonials

- Pricing and lead times — balancing cost, quality, and delivery schedules

- Environmental and sustainability commitment — aligning with your corporate responsibility goals

DeepMould excels in all these areas, making it a top choice for companies seeking reliable, innovative, and comprehensive manufacturing solutions.

Conclusion: Embracing the Future of Manufacturing with Confidence

In conclusion, the fields of metal fabrication and plastic injection molding manufacturing are vital to the modern industrial ecosystem. Companies like DeepMould exemplify how leveraging cutting-edge technology, sustainable practices, and a customer-centric approach can produce outstanding results. As industries continue to evolve, embracing these advanced manufacturing techniques will be key to maintaining competitiveness, ensuring product quality, and driving innovation.

Whether you are looking to develop complex plastic components or durable metal parts, partnering with a proven expert will make all the difference. By understanding the nuances of each manufacturing process and selecting the right partner, your business can thrive in today's competitive market and adapt to future challenges with confidence.